Sandblasting is a technique, similar to waterblasting, that is used for surface preparation, restoration, and more. It is a versatile method that can be used in many circumstances both industrial and commercial. While waterblasting is also a great choice when it comes to these applications, sandblasting can work effectively on a wider range of surfaces with greater removal of tough coatings or paint because of the abrasive properties.

What is Sandblasting?

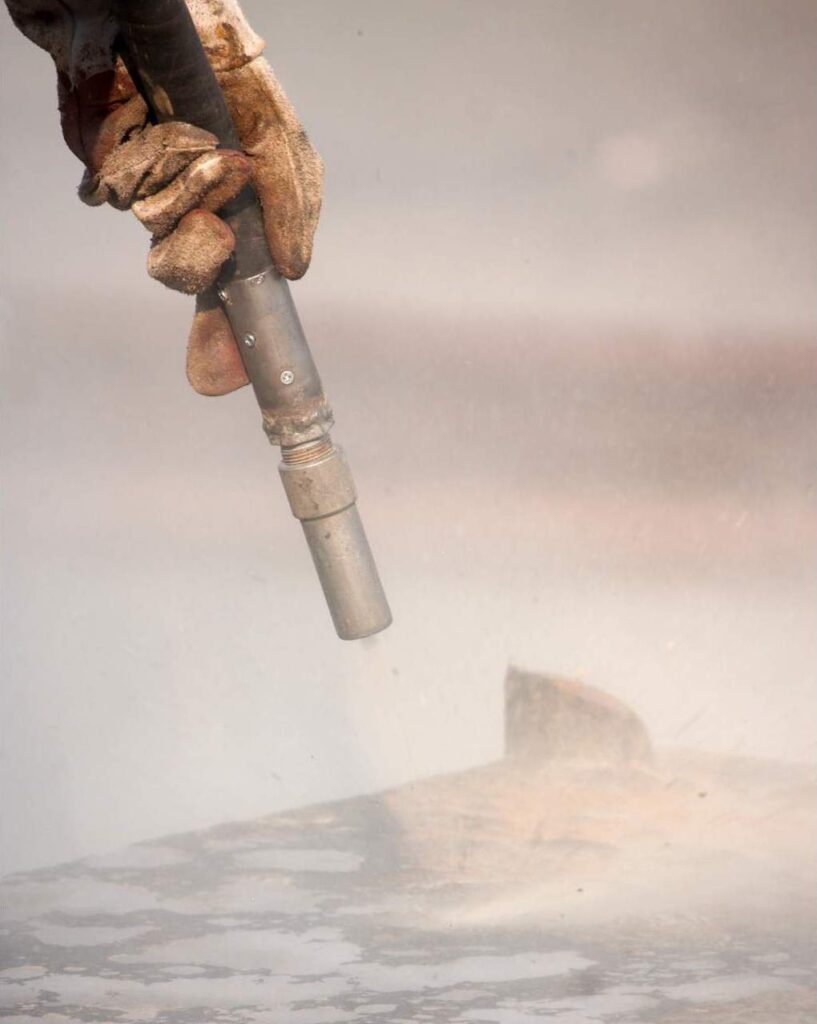

This technique uses special equipment to propel abrasive materials, typically sand, at a surface. Sandblasting is perfect for removing contaminants, rust, old coatings, and paint. It is used to clean and strip a surface to prepare it for a new coating or paint or to improve the look.

The Sandblasting Process: Step-by-Step

Surface Prep – Before the sandblasting process can begin, the surface needs to be cleaned and prepared. Cleaning and degreasing the surface will ensure that any extra oil, grease, and dirt doesn’t contaminate the surface treatment. Any surrounding area that is not being treated needs to be covered by a plastic sheet and tape to protect it from the abrasive material.

Adjusting Pressure Settings and Loading Sand – Once the surface is cleaned and ready for the treatment, it is time to prepare the sandblasting equipment. Settings, material chosen, and blasting technique will depend on the material of the surface and the goal for the project.

Sandblasting the Area – Our trained and experienced employees performing the service will monitor the sandblasting process to ensure they are achieving the desired quality and results. The operator will blast the sand directly at the surface and adjust as needed. It is important to follow proper safety precautions during the blasting process because it can generate dust and airborne sand particles which can cause respiratory issues. Protective equipment is required during the blasting to prevent this and other hazards.

Cleaning and Post-Inspection – After the treatment, our team will remove any residual sand particles and clean the surface. They will also inspect it to ensure that the surface has the desired result. Once the surface is cleaned and passes inspection, a sealant, coating, or waterproof membrane can be applied to prevent water infiltration.

Overall, sandblasting is a versatile method that can be used on concrete, brick, stone, and metal. It is great for cleaning and prepping surfaces. The equipment allows for precise treatment which helps achieve consistent results. To learn more about the sandblasting process and how it could be beneficial for your company, contact us through our website here.