Top Structural Issues in Commercial Buildings and Prevention Tips

When you own a commercial building one of the top priorities is safety. The second top priority is protecting your investment. Structural issues in commercial buildings can quickly lead to costly repairs that can be a financial strain on the business or complete building failures in extreme cases.

What can cause Structural Issues in Commercial Buildings?

Structural Issues can be caused by a number of factors and often have multiple contributing factors to the issue. When planning and constructing your building, you want to make sure you’re working with reputable contractors that are using high-quality materials. Inadequate building practices and subpar materials can compromise your building’s structural integrity. Wear and tear without the proper maintenance can also have a negative impact on your property. Materials and waterproofing systems need to be updated as your building ages or it could cause degradation of the material and water infiltration. Outside forces such as hurricanes and temperature fluctuations can also cause structural damage.

Top Structural Issues in Commercial Buildings

Corrosion: If your building has leaks or is not properly waterproofed, the metal components such as structural steel and beams, can rust and corrode. If concrete is not properly sealed, the rebar can corrode causing the concrete slab to crack and chip.

Foundation Issues: Soil expansion and uneven settling can cause your foundation to be misaligned. This causes cracks in the foundation, walls, or ceilings.

Uneven Floors: Uneven or sagging floors can be a result of foundation issues, overload, or deterioration of support elements.

Water Damage: Water infiltration can be caused by structural issues and only exacerbates the problems. If you see stains on walls or ceilings or white, powdery residue on brick or concrete, these could be signs of water damage.

Tips for Prevention

When it comes to structural issues in commercial buildings, it’s best to take a proactive approach. This will prevent small issues from turning into large, costly repairs.

Training: If you have maintenance or management staff, make sure they know the signs of structural damage and create an easy way for them to report it to you. If the building has tenants or other businesses that rent spaces from you, ensure that they know to report any leaks or cracks that may occur.

Waterproofing: Keeping your waterproofing systems up-to-date will prevent water infiltration and slow down wear and tear on your building. Below-grade and negative-side waterproofing will prevent water infiltration around your foundation. Sealants and coatings used on walls, window frames, expansion joints, and concrete slabs will prevent water from breaking down your building’s materials.

Structural Inspections and Regular Maintenance: Regular inspections will ensure that your building is up-to-code and you can address any issues that may arise. Any leaks or cracks should be addressed immediately to prevent further damage.

Our team is here to help with your structural inspections and waterproofing needs. Learn more about our structural inspection process here or contact us through our website to talk to one of our trained professionals about your building’s needs.

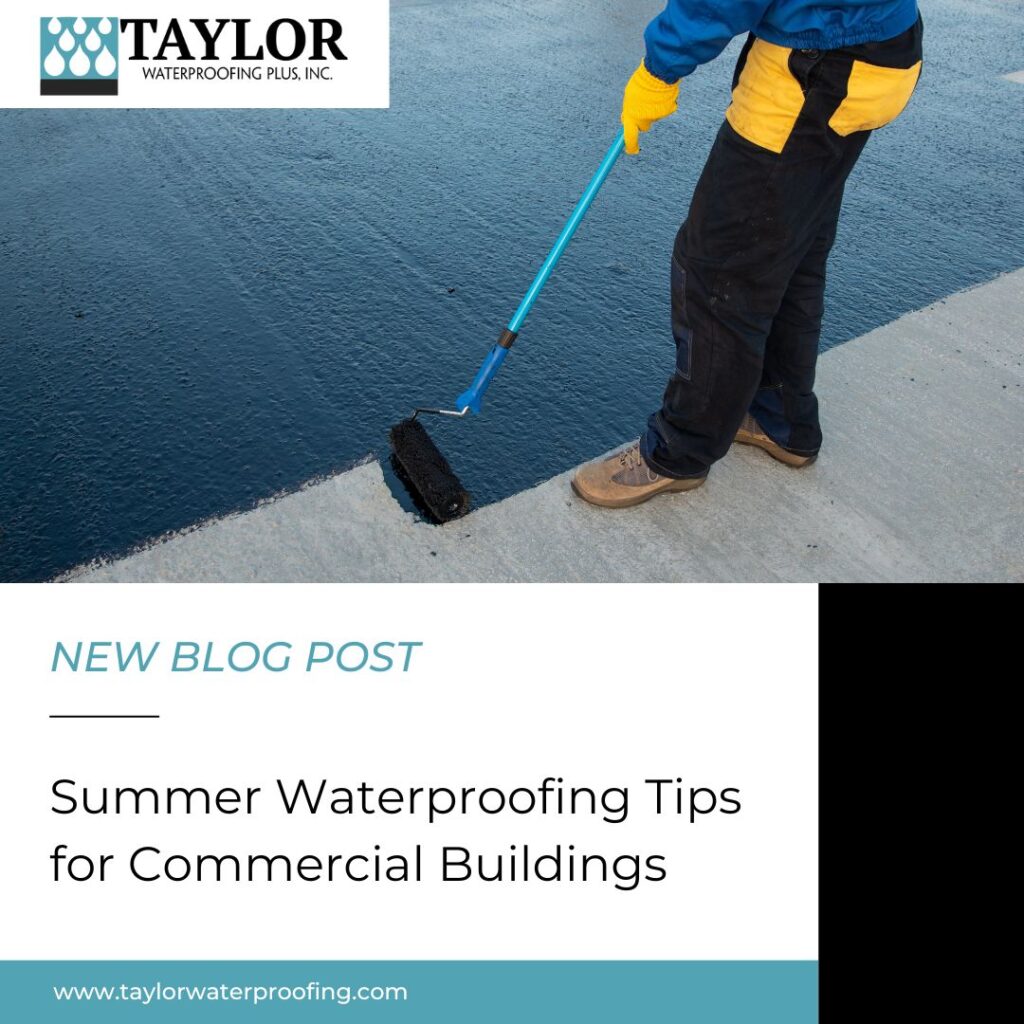

Summer Waterproofing Tips for Commercial Buildings

Not having efficient waterproofing can cause water infiltration and increase maintenance costs. Using our summer waterproofing tips and keeping your waterproofing up-to-date, especially in the summer when humidity is at a high, will protect your building and ensure safety.

Summer Waterproofing Tips

Keep an Eye on Energy Cost – Leaks in your commercial building can cause your electricity bills to skyrocket. When water leaks onto insulation, it reduces its effectiveness, causing heat gain. In return, your HVAC system has to work harder to maintain cool temperatures inside. Leaks could also be letting warm air into your building, reducing the effectiveness of your HVAC system.

Seal Windows and Doors – Windows and doors can be a vulnerable area in your building and prone to water leakage if not sealed properly. There are many techniques that can be used to waterproof these areas. Weatherstripping can be used around door frames to reduce air loss. Wet glazing, caulk, and sealants can be used on commercial windows to prevent water infiltration and seal the area.

Waterproof Basements – As humidity rises, moisture can build up in your basement, causing the walls, flooring, and ceilings to become damp. Over time, the water can seep through the concrete causing many issues including rust and corrosion. Negative-side waterproofing and concrete coatings are great ways to waterproof your basement and foundation.

Exterior Walls – During the summer months, there often storms that bring high amounts of rain. This can have an impact on masonry exterior walls. Elastomeric coatings and other water-repellant sealants are great for external materials.

Update Waterproof Membranes if Needed – Like any other part of your commercial building, waterproof membranes require maintenance. Wear and tear, foot traffic, chemical exposure, and other factors can break down the sealants or coatings leading to leaks. As we go deeper into hurricane season, it’s even more important to make sure these waterproof coatings and membranes will protect your building and prevent water infiltration.

Failing to maintain and update waterproofing systems as needed can lead to costly repairs and increase your maintenance expenses. Ensuring your building’s waterproofing membranes and systems are up-to-date will protect your commercial building from the high humidity of summer and help you save on energy costs. For more information and summer waterproofing tips, check out our blog here or contact us through our website here.

Storm Repairs and Inspections: Assessing Hidden Damage in Your Commercial Building

With Hurricane Beryl hitting the Houston area hard, it is important to ensure that your commercial building is still structurally sound and protected against water damage. With the amount of wind and rain the storm brought, there could be visible and hidden damage to your building. Our team can help you assess the damage with storm repairs and inspections and understand the steps to make sure your building is safe and not in danger of leaks and water infiltration.

Initial Assessment

The first step after an extreme weather event is to make sure there is no damage that is an immediate danger to your or others’ safety. Examples of this could be broken glass, gas leaks, or extreme structural damage. As you are inspecting the building, take photos of any visible damage for insurance purposes.

Water Damage

Water intrusion can happen after a storm of this magnitude. If you see water damage or leaks, setting up fans and dehumidifiers will help prevent further damage until repairs can be made. Our team can address these visible leaks and will also check for leaks that may be hidden. While the areas that are damaged might have been waterproofed in the past, it’s important to keep in mind that the age of the waterproofing membrane or system and the extreme weather conditions are both factors in how well the membrane will hold up.

Structural Integrity

Strong winds and heavy rainfall can cause unparalleled damage to commercial properties. Often these damages go unnoticed by the naked eye until they start to cause problems down the road. If these damages are left unrepaired, it can lead to building failure and costly repairs.

Structural Damage that can be caused by Storms:

Exterior Walls: The pressure from high winds can cause your building’s walls to develop cracks and gaps.

Foundations: Strong wind and large amounts of flowing water can cause soil erosion and lead to the foundation being damaged.

Windows and Doors: These are vulnerable areas of the building. High winds and flying debris can damage and crack the frame around windows and doors, leading to water infiltration.

Framework: Support beams and columns will need to be inspected after a storm to ensure they are not damaged by pressure, debris, or water infiltration.

Our team is here to help you get your building back in working order and ensure it is protected from further damage. We offer comprehensive storm repairs and inspections so you can rest assured that your building is assessed for not only visible damage but also hidden damage that can risk the occupants’ safety and lead to expensive repairs. Learn more about our waterproofing solutions in our blog or reach out to us through our website here to talk to a team member.

Commercial Waterproofing FAQs

To protect the longevity of your commercial building and maintain structural integrity, it is crucial to waterproof the building and the building’s materials. There are many causes for water infiltration and having a comprehensive waterproofing maintenance program will prevent costly damage. Below are some of the most common commercial waterproofing FAQs we get.

Does the interior and the exterior need to be waterproofed?

Yes, both the interior and exterior of your commercial building need to be waterproofed to ensure that it is completely protected from water intrusion. There are different waterproofing techniques to protect both the inside and outside of your building but are both equally important when it comes to combating leaks and extending the life of the building.

How do I know when it’s time for maintenance?

If you see any signs of water damage, including damp spots, musty odors, water stains, or peeling paints, contact a waterproofing professional immediately. If you are seeing these signs, there is a leak somewhere in the building that needs addressing. If there are no signs of water damage or other issues that need immediate attention, a yearly inspection will determine if the sealant, waterproofing membrane, or system needs updating.

How long will the waterproofing last?

There are many factors that go into determining how long a waterproofing system will last. Most last around 10-15 years, but some can last up to 20 years. Some of the factors include the quality of material used, chemical exposure, foot traffic, and moisture levels.

When should I waterproof my building?

A lot of the waterproofing systems, such as below-grade waterproofing are done during the construction phase of the building, but there are still many techniques that can be done on existing buildings. Any waterproofing system that is external should be applied when it is not raining to ensure proper adhesion.

What services does Taylor Waterproofing offer?

We offer many waterproofing services including:

- Waterblasting and Sandblasting

- Deck Coatings

- Epoxy Flooring

- Building and Parking Garage Structural Inspections

- Balcony Repairs

- Interior and Exterior Wall Coatings

- Water Testing

- Commercial Window Waterproofing Services

- Below-Grade and Negative-Side Foundation Waterproofing

- Concrete and Masonry Repair and Waterproofing

- & More!

Learn more about the services we offer on our Service Page here or check out our Blogs here.

If you have any questions on how to protect your commercial building from water damage and infiltration that we didn’t get to in our commercial waterproofing FAQs, our team is here to help! Contact us through our website here to talk to one of our experienced team members.

Waterproofing Solutions for Healthcare Buildings

When you own a healthcare building, it is important to provide a safe and healthy environment. Implementing these waterproofing solutions for healthcare buildings and a maintenance plan, will not only support a hygienic setting but save you money on large repairs in the future.

Importance of Waterproofing in a Healthcare Setting

Water infiltration and damp materials can cause health issues for your staff and patients. Water damage can also weaken the structure of the building, putting your occupants at risk. There are building codes and standards that healthcare buildings must meet to be in compliance. Waterproofing will ensure that your building is protected from water intrusion and in compliance with these regulations. Properly waterproofed buildings are more energy efficient than buildings that have leaks. This will save you money on energy costs.

Waterproofing Solutions:

Exterior Wall Coatings – These coatings are the first line of defense when it comes to protecting your building from water infiltration. Not only do they stop water from entering the building, but they also keep the exterior looking nice. Exterior wall coatings are created from elastomeric materials and come in many styles and colors so you can choose the one that best fits your building’s needs.

Epoxy Flooring – In a hospital or healthcare environment, it’s best to choose a flooring that offers multiple benefits. Epoxy flooring is a durable and low-maintenance option. Because it is seamless and non-porous, it prevents bacteria and dirt build-up. This also makes it easy to clean and disinfect. Additives can be mixed with it to make the flooring slip-resistant, helping to reduce the risk of falls.

Window Waterproofing – Windows can be a major area for water intrusion. Ensuring that windows are properly sealed and waterproofed will help maintain a healthy environment. Our team uses several techniques such as wet glazing, flashing, and sealants to prevent water infiltration.

Hygienic Coatings – Treating surfaces with an antimicrobial sealant or coatings helps maintain cleanliness and prevents bacteria growth. Hygienic coatings can be used on floors, walls, ceilings, expansion joints, and more. Along with being antimicrobial, these coatings are chemical resistant and suitable for high-traffic areas.

These waterproofing solutions will help keep your patients and staff safe and protect the longevity and durability of the building. To learn more about waterproofing solutions for healthcare buildings, contact us through our website here or check out our blog for more resources.

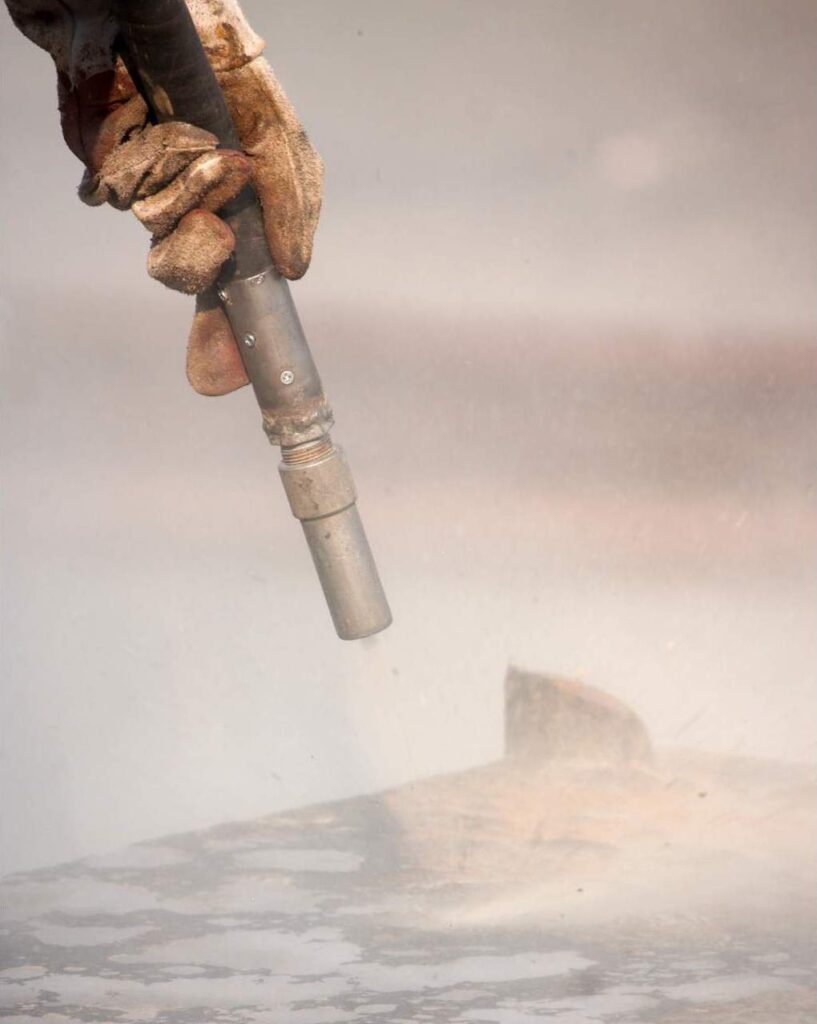

Sandblasting Process

Sandblasting is a technique, similar to waterblasting, that is used for surface preparation, restoration, and more. It is a versatile method that can be used in many circumstances both industrial and commercial. While waterblasting is also a great choice when it comes to these applications, sandblasting can work effectively on a wider range of surfaces with greater removal of tough coatings or paint because of the abrasive properties.

What is Sandblasting?

This technique uses special equipment to propel abrasive materials, typically sand, at a surface. Sandblasting is perfect for removing contaminants, rust, old coatings, and paint. It is used to clean and strip a surface to prepare it for a new coating or paint or to improve the look.

The Sandblasting Process: Step-by-Step

Surface Prep – Before the sandblasting process can begin, the surface needs to be cleaned and prepared. Cleaning and degreasing the surface will ensure that any extra oil, grease, and dirt doesn’t contaminate the surface treatment. Any surrounding area that is not being treated needs to be covered by a plastic sheet and tape to protect it from the abrasive material.

Adjusting Pressure Settings and Loading Sand – Once the surface is cleaned and ready for the treatment, it is time to prepare the sandblasting equipment. Settings, material chosen, and blasting technique will depend on the material of the surface and the goal for the project.

Sandblasting the Area – Our trained and experienced employees performing the service will monitor the sandblasting process to ensure they are achieving the desired quality and results. The operator will blast the sand directly at the surface and adjust as needed. It is important to follow proper safety precautions during the blasting process because it can generate dust and airborne sand particles which can cause respiratory issues. Protective equipment is required during the blasting to prevent this and other hazards.

Cleaning and Post-Inspection – After the treatment, our team will remove any residual sand particles and clean the surface. They will also inspect it to ensure that the surface has the desired result. Once the surface is cleaned and passes inspection, a sealant, coating, or waterproof membrane can be applied to prevent water infiltration.

Overall, sandblasting is a versatile method that can be used on concrete, brick, stone, and metal. It is great for cleaning and prepping surfaces. The equipment allows for precise treatment which helps achieve consistent results. To learn more about the sandblasting process and how it could be beneficial for your company, contact us through our website here.

Waterproofing Solutions for High-Traffic Commercial Areas

Over time, foot traffic or the presence of heavy machinery can cause wear and tear that leads to water infiltration. In commercial and industrial settings subject to such high traffic, neglecting this issue can result in significant damage and potential hazards. Our team offers waterproofing solutions for high-traffic commercial areas to protect and preserve your building.

Why it’s Important to Waterproofing These Areas

Waterproofing is a preventative measure that is essential to preserving the structural integrity of your commercial building. Foot traffic or heavy machinery in places like a parking garage, warehouse, or retail space, can become damaged due to the constant activity and friction. This can cause safety hazards and result in costly repairs down the road for your business. Waterproofing these areas and using durable materials will help mitigate the damages.

Durable Flooring: Selecting flooring that will last is a must for areas that receive a lot of foot traffic. Epoxy is an option that is great for both commercial and industrial spaces. This flooring is seamless, and water, chemical, and abrasion-resistant. This makes it ideal for high-traffic areas.

Waterproofing Concrete: Concrete can become susceptible to water infiltration over time, causing cracks, spalling, scaling, and corrosion. Our team offers sealants and coatings that are applied on the surface of the concrete, creating a barrier against moisture.

Sealant for Expansion Joints: Over time, buildings naturally expand and contract with temperature and humidity changes. Expansion joints are designed to absorb these movements to protect the building from damage. If left unprotected, expansion joints can be a vulnerable point for water infiltration. Oftentimes, a silicone or polyurethane sealant is used to waterproof expansion joints due to their flexibility.

Maintenance Tips for High-Traffic Areas

Regular inspections are important to maintain waterproofing systems in commercial buildings and help ensure longevity. If you conduct regular inspections, any damage or issues caused by wear and tear will be caught before any serious damage can be done. It is also important to promptly repair any damage seen during these inspections. Keeping the areas clean and free of debris will reduce the amount of buildup that could negatively affect the sealants. When cleaning the area, use a gentle cleaner and avoid using harsh chemicals to prevent the waterproofing materials from degrading.

To learn more about waterproofing your commercial building and the waterproofing solutions for high-traffic commercial areas our team offers, contact us through our website here.

Waterproofing Essentials for Commercial Buildings

The waterproofing essentials for commercial buildings will enable you to get ahead of the damage and issues that water infiltration can cause. Leaks and water intrusion can cause a host of problems such as mold growth, structural damage, pest issues, and stains and discoloration on walls and ceilings. By using sealants and coatings on your building’s surfaces with the proper waterproofing methods and techniques, you can mitigate these issues effectively and protect your commercial building.

Commercial Foundations

There are two ways to waterproof a commercial foundation; below-grade and negative-side. Below-grade waterproofing is the method that’s done during the construction of the building. This application creates a barrier between the foundation and the soil and earth around the building by applying a fluid-applied seamless membrane, sheet systems, or a combination. This system increases the longevity of the structure and prevents flooding.

Negative-side waterproofing addresses water infiltration from the inside by applying sealants or a waterproof membrane to the foundation’s walls and slab. This prevents water from entering the interior of your building.

Exterior Walls

Elastomeric coatings are made from epoxy, urethane, or silicone and create a moisture barrier for your building’s exterior walls. These coatings prevent your walls from corrosion and protect against chemicals and UV rays.

Commercial Windows

It is important to ensure that your windows are equipped with the proper flashing or waterproofing system. This will protect the window frame from water finding its way in through the seams. Wet glazing is a technique that is also commonly used in commercial applications due to the benefits it offers. This method creates a watertight seal that is highly weather-resistant and durable. Wet glazing is the process of applying a sealant around the perimeter of the glass panel, forming a bond between the glass and the frame.

Structural Concrete

Over time, structural concrete slabs can become vulnerable to water intrusion. Applying a sealant or coating to the slab creates a waterproof membrane and protects the concrete from corrosion, cracks, and water damage.

Our team of waterproofing professionals can help you navigate the waterproofing needs and the waterproofing essentials for commercial buildings. Contact us through our website here to learn more.

Commercial Deck Coatings

Applying a deck coating adds a protective layer to your commercial decks. These coatings are durable, waterproof, and come in different colors, and finishes. Having a professional waterproofing team applying deck coatings ensures that the proper materials are used and installed correctly. Before applying the coating, our team inspects the deck, cleans the surface, and makes the proper repairs to make sure your coating lasts for as long as possible.

What is Deck Coating?

Deck coatings are a layer of sealant applied to your commercial building’s decks. This can be applied on parking decks, balconies, walkways, roof decks, wooden decks, patios, and more. Coatings can be pedestrian grade or vehicular grade and come in all different forms.

Types of Coatings

Acrylic – This water-based coating is UV-resistant and great for decorative applications. It has great adhesion to many different surfaces. Acrylic coatings aren’t as durable as some of the options below, so if you need a coating on areas that are high-traffic like a parking deck or walkway, epoxy or polyurethane would probably be a better choice.

Epoxy – Epoxy is a versatile material that can withstand heavy foot traffic and is resistant to chemical exposure. This makes it great for industrial and commercial applications. It is often used in warehouses, retail stores, and restaurants. Epoxy is available in different colors so it can be customized to fit the look you’re going for.

Polyurethane – This flexible coating is UV and abrasion-resistant, making it ideal for outdoor use. Polyurethane can be used on wood, concrete, and metal. It is also great for high-traffic areas.

What are the Benefits of Commercial Deck Coatings?

- Waterproofing Your Building – All of the deck coating our team applies helps prevent water intrusion and leaks.

- Slip-Resistant – Many of the materials commercial buildings are made with can become slippery when wet. Coatings can be textured to help prevent falls in areas where people walk.

- Durable – With proper installation and maintenance, deck coatings can last up to 10 years. The materials can withstand harsh weather and chemicals without wearing away.

- Fits Your Aesthetic Needs – Deck coatings can be applied in different colors to match your building’s aesthetic. It also helps to keep your building looking new.

- Increases Deck’s Lifespan – Because deck coatings are resistant to mechanical, UV, weathering, and chemical damage, it will protect the surface from corrosion.

Our team of waterproofing professionals is here to help you with all of your deck coating and sealant needs. Contact us through our website here to learn more.

Why Should You Waterproof Your Commercial Building?

As a building owner or property manager, waterproofing your commercial building is an important part of contributing to the longevity and safety of your building. When you waterproof your commercial building, it is a proactive measure that prevents water damage and other related issues. Waterproofing is an essential component of any building maintenance program.

Reasons to Waterproof Your Commercial Building

- Protect Your Investment: Waterproofing helps preserve your building and prevents damage. Water damage can cause aesthetic and structural issues. Preventing these problems will allow you to maintain property value. You will also protect any interior assets, such as computers, furniture, inventory, and equipment, from being damaged by preventing potential leaks and flooding.

- Reduce Maintenance and Repair Costs: Waterproofing your building is an upfront cost that saves you money in the long run. The longer a leak or water damage is left, the more expensive it will be to repair and replace the materials. When you invest in waterproofing, you are reducing energy consumption and reducing energy costs by preventing air and water leaks and helping to regulate the indoor temperature.

- Prevent Mold and Mildew: If water damage isn’t resolved and water sits for extended periods of time on the drywall and insulation, mold and mildew will develop. By preventing moisture accumulation, you can reduce the health risks associated with mold and mildew and improve the air quality for your building’s occupants.

- Extend Your Building’s Lifespan: By preventing these damages and making the most out of your maintenance plan, you increase the longevity of your commercial building. A well-maintained building is one that lasts.

- Maintain Your Building’s Safety: Water infiltration can compromise your building’s structural stability. Water damage weakens your building and reduces its durability. These can cause major long-term issues and threaten the safety of the building. This can also cause you to not be in compliance with building codes and safety regulations.

Whether you are seeking guidance on preventative measures or solutions for existing issues, we’re here to provide the expertise you need. Our team of skilled professionals is dedicated to addressing any concerns you may have regarding commercial waterproofing and your building’s longevity. Contact us through our website or delve deeper into our services by exploring our informative blog here.